Innovative New Method for Vehicle Aerodynamic Simulations describing the the recently-released white paper: Scaling New Heights in Aerodynamics Optimization: The 50:50:50 Method, co-authored with Ashok Khondge.

The topics are the Current Role of CFD in Aerodynamic Design, the 50:50:50 Method, Meshing and Defining Computational Domain, Defining Shape Parameters, Morpher Setup, Sampling Design Space, Automated Simulation, Response Surface Data and Sensitivity Analysis.

Abstract

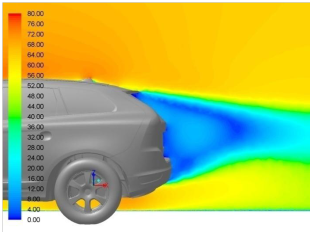

Aerodynamics development is all about trade-offs, striking the right balance between styling needs and aerodynamic concerns. Nearly all major automotive and truck manufacturers use computational fluid dynamics (CFD) during the development process to evaluate aerodynamic drag of proposed vehicle designs.

Typically, R&D teams analyze about 50 to 500 different vehicle shape variants in the time available for aerodynamic development.

The analysis results shed considerable light on the impact of styling choices on aerodynamic performance, but they do not come close to achieving the potential of simulation to identify the best possible design that meets the various constraints and trade-offs involved in the project.

Recently, a number of enabling technologies have converged, making it possible to automatically simulate enough vehicle shapes over the duration of a weekend to accurately define a large aerodynamic design space.

By understanding performance over a large design space, aerodynamics engineers can provide detailed guidance to stylists about the specific effects on drag of numerous shape parameters — such as boat tail and front spoiler angles — in the form of response surfaces, sensitivity charts, Pareto plots and trade-off plots.

Armed with this information, stylists and aerodynamicists can then identify the vehicle shapes that yield the least possible drag while adhering to styling themes and other constraints.