Aerospace

Today, all the modern manufacturing enterprises are striving to develop the best optimized, reduced weight and cost effective products that meet the intended design functionality and reliability.

Today, all the modern manufacturing enterprises are striving to develop the best optimized, reduced weight and cost effective products that meet the intended design functionality and reliability.

In this scenario, structural optimization tools like topology and shape optimization with manufacturing simulations are becoming attractive in product design processes.

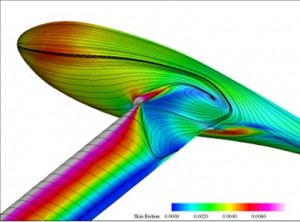

These tools also in help reducing product development times. CFD analysis is routinely employed in the aerospace industry.

It is essential for organizations wishing to test and optimize their design solutions.

Example Applications

- External flow-exposed surfaces such as wings and appendages

- Engine installation, intake and exhaust ducts

- Aeroengine turbines and compressors

- Airplane propellers and rotors

- Auxiliary ducts and nozzle

Check out our case studies where some aerospace examples are listed.