It’s now aviable the article published by RBF Morph on the EnginSoft Newsletter Year 16 n°3 Autumn 2019 that describes uses Adjoint and BGM shape-modification approaches for mesh morphing.

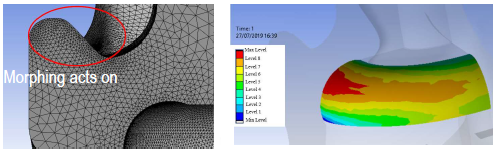

With automatic surface sculpting, the morphing action can be guided by the physics of the model that is being analyzed, allowing engineers to automatically identify the surface zones whose nodes should be moved inwards or outwards to achieve the optimization objective, saving on the time required to complete an optimization process.

The study presented in colloaboration with the Italian company SACMI Imola S.C. aims to demonstrate how to perform product optimization automatically, saving on the time required to complete an optimization process.

The proposed optimization strategy involves the use of numerical simulations and consists of combining mesh morphing with one of two shape-modification approaches dictated by the physics of the model being analyzed, namely the Adjoint approach or the BGM approach.

Both automatic sculpting approaches were used to optimize the component’s stress levels.

The Adjoint-based approach was successfully applied to the area identified and resulted in a maximum stress reduction of 11.6% on the surface shown.

For a comprehensive read of this engaging discussion, we invite you to explore the full article by following this link.