The Analysis and Codes Group at Fusion for Energy (F4E) recently joined the Experiment n. 12 CAEUp “Update of CAE models on actual manufactured shapes” of the Cloudifacturing EU Project “Cloudification of Production Engineering for Predictive Digital Manufacturing” as a stakeholder.

The Experiment CAEUp aims to implement and assess a procedure to offer manufacturing industries a service to enhance the quality control, based on the digital twin concept.

The end user provides both the CAE model (digital twin of the nominal design) and the surface representation of the individual measured part. The digital twin is then updated on HPC cloud and the performance indexes of the component are recomputed adopting a variation of the CAE model shaped as the actual manufactured part.

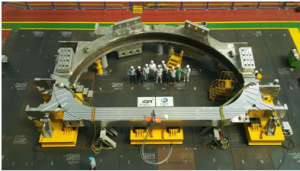

The adaption of digital models (both CAD and CAE) onto the “as built” shape is specifically felt to successfully build ITER; this is why F4E engineers are willing to test how the experiment works for a specific part, using the recently manufactured Toroidal Field Coils #9 (TFC#9) of the ITER tokamak. F4E is investigating how RBF Morph technology can be used the update of the CAE and the CAD model of the TFC#9 to match the actual “as built” shape as acquired by high resolution blue light scanner.