RBF Morph is a pioneer and leader in mesh morphing technology, which is now integrated with LS-DYNA and ANSYS Workbench and Mechanical for crashworthiness optimization. The integration of RBF Morph and LS-DYNA provides the ability to explore shape variants without recreating a new model, reusing the FEA model of a similar car at an early-stage design of a new car.

In the automotive industry, the study of a new shape for a vehicle in production can start from the modification of a model previously realized, and of which the CAD-design and/or the computational grid are already available. Additionally, sometimes there is the necessity to adapt the shape of one model to a completely different one to study its properties and its crash behavior. The use of mesh morphing involves a substantial saving of time since the realization of the new computational grid and the preparation of the FEM model are avoided. Building a new FEM model using a re-meshing approach can be complex and wasteful.

However, there are some requirements about the perfect matching between the style surface and the morphed FEM that must be satisfied. These requirements include having the same platform (hinges, connections), keeping the same cross-section, preserving welding through geometrical constraints, and not accepting discontinuities. The quality of the computational grid must also be preserved.

To apply mesh morphing, RBF Morph Structures is used, which is directly integrated into the Workbench interface for Ansys Mechanical and its LS-DYNA extension. This allows the use of both Mechanical’s implicit solver and LS-DYNA’s explicit one. RBF Morph Structures provides direct shape changes within the Ansys Workbench environment, the ability to quickly edit LS-DYNA keyword files, and flexibility and ease of use with a consistent Ansys-like user interface.

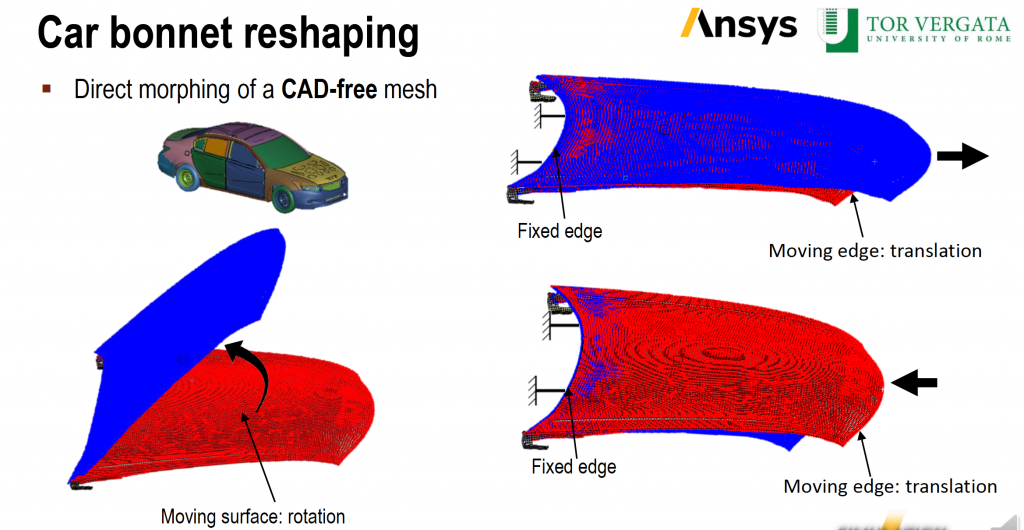

In the example presented at Ansys Simulation World 2021, the integration of RBF Morph and LS-DYNA is demonstrated for the case of a car bonnet showing how the morphing allows to transform the hood of one car model onto that of another. The reconstruction of support guide surfaces on the mesh can increase the size of the mesh reinforcements of the adapted car. From a dead mesh to a supporting CAD, the desired mesh shapes can be quickly rebuilt. A parametric study of component shapes and positions typical of the structural design can be performed, allowing for easy design and shape optimization coupled with LS-DYNA’s explicit solver.

In conclusion, there is a need for advanced tools to explore shape variants in the crashworthiness field. Mesh morphing is an excellent tool to reuse existing and validated FEA models. In this study, a new approach based on LS-DYNA, ANSYS Mechanical, and RBF Morph was presented, allowing for the prediction of the crash of a reshaped car bonnet without the need for a new FEA mesh, in particular the bonnet of a Honda Accord was adapted onto the one of a Chevrolet Silverado getting the target crash behavior.